We create innovative and “custom” plastic and composite materials

Specialists in 3D printing

IRMA (Institut Régional des Matériaux Avancés) is a technical center created in 1990 and based in the Lorient basin in the heart of Sailing Valley. Irma offers high quality services in plastic and composite additive manufacturing in small series for aeronautics, yachting, packaging…

More precisely, we design innovative plastic and composite materials, manufacture, and market complex parts with “custom” formulations at the request of our customers.

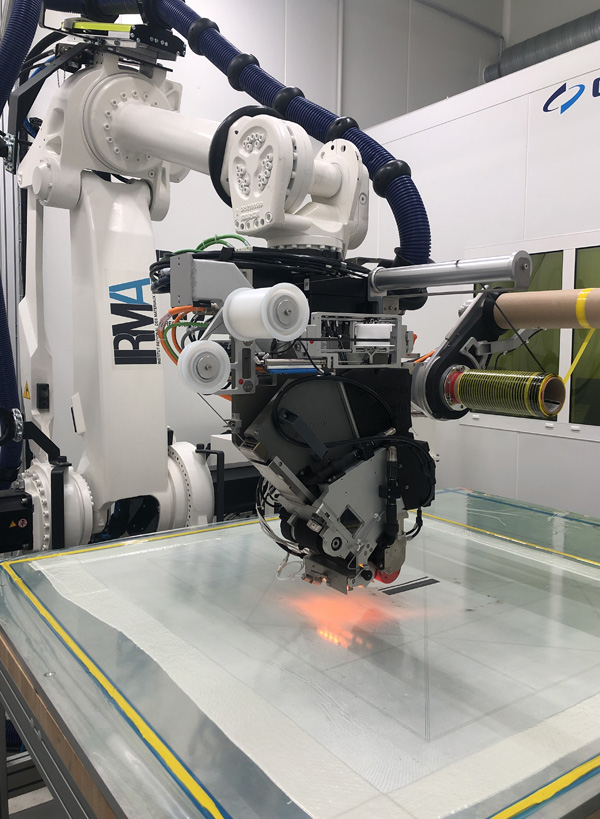

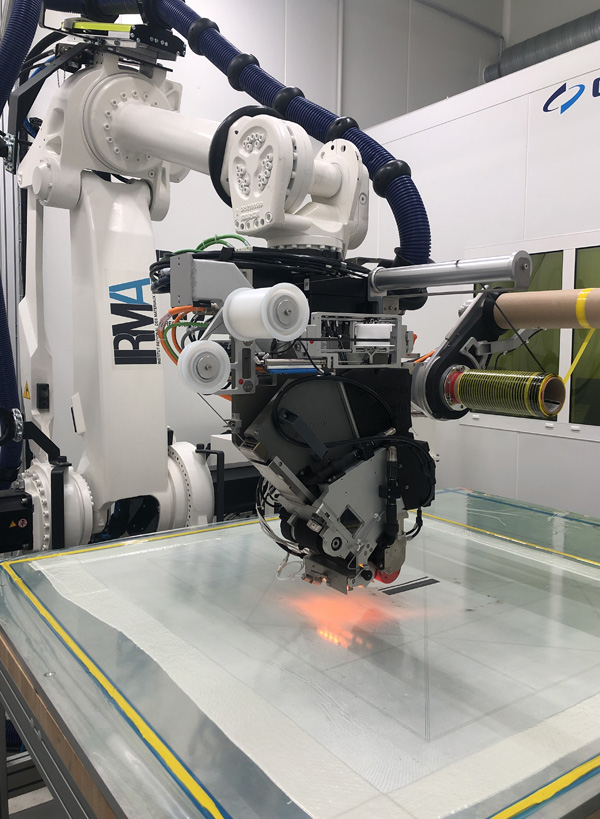

We are specialized in 3D printing: parts in composite materials based on short fibers (FDM), long fibers (FDM assisted by extrusion) and continuous fibers (automated fiber placement AFP and filament winding).

We perform mechanical, chemical, biological and other tests on demand.

Our services

Low-impact materials

IRMA

Team

Passionate about engineering, our team

is agile and environmentally engaged

“Elected by the Board of Directors, I act on its behalf to ensure that the association’s activities are consistent with its purpose. I report regularly to the directors and members on the association’s operations and accounting results. This voluntary role obviously does not allow me to participate directly in the work of innovation, which I leave in the full confidence of our team of experts. However, I don’t hesitate to put forward my point of view as an industrialist when given the opportunity!

Together with the General Director and the Scientific Director, we devise and implement the Institute’s strategic roadmap and ensure that the material and human resources are commensurate with our ambitions. Together, we are striving to take the decisions that will ensure the long-term future of IRMA, a wonderful tool for the economic development of our region.

Maxime Delbury

CEO

“After a ‘handful’ of previous experiences directing interesting projects and R&D departments at large corporate groups, accompanying growing SMEs and developing a technology start-up in Lorient, I was contacted in 2020 to develop jewel of a project: IRMA. This new challenge called on all of my business management and development skills: I had to develop companies’ knowledge of the expert skills of our group and participate in the development of the territory around IRMA’s materials skills.”

Frédéric Fourreau

General Director

” “

Yves Grohens

Scientific Director

“Supporting managers in their strategy, implementing projection and reporting tools to help them manage on a day-to-day basis and manage in the medium and long term. These are just some of the tasks I have carried out for the companies and organizations I have worked for over the course of my career.

At the end of 2021 I joined the IRMA team, its values and its world. What’s the link with my past experiences? My common thread has been working in a wide variety of activities, always at the service of local development.

My aim is to put my skills and experience at the service of IRMA’s young, competent and committed team, and to help the organization contribute, through its field of expertise, to the influence and development of the region.”

Pascale Pérou

Administrative and

financial manager

“After more than 20 years of experience in the field of early childhood education, I wanted to start a professional reconversion to get closer to the scientific and technical fields that I am passionate about. By integrating the BTS GPME (management of small and medium-sized companies), IRMA gave me the chance to validate my diploma after 2 years of learning in alternation. I am now an administrative assistant at IRMA. I oversee the administrative and financial management of the structure (customer-supplier relations, accounting, and human resources) and communication on social networks. I am looking forward to working in a dynamic team, participating in various innovative activities related to the maritime issues of the territory, and relieving the engineers of administrative tasks.”

Hélène Marcel

Administrative assistant

“After a general engineering degree in Lille and a 1-year course in Germany to specialise in technical textiles, I began my career at Centexbel, the Belgian industry’s textile research center in Liege and Ghent. I spent 7 years there learning how to set up and manage private and collaborative R&D projects. I then joined the EuraMaterials competitiveness cluster in Northern France to support the SME and ETI ecosystem in the areas of functional textiles, sensor integration and innovative materials. I also performed technical services for large companies.

Attracted by the sea and sailing, I joined the IRMA team in 2023 to develop the business. My role is to promote the team’s skills, help you define your needs and set up R&D projects.”

Virginie Canart

Industrial partnership manager

‘Following my training as a marine resources engineer specialised in marine biotechnology and my experience working at the Marine Biotechnology and Chemistry Laboratory (LCMB), I decided to pursue the topic of materials biodegradation.

As the person responsible for IRMA’s environmental impact pillar, I possess expertise in the fields of eco-toxicology and material biodegradation. I am currently working on multiple projects, one of which has the goal of creating French regulations in the context of the biodegradation of plastic materials in marine environments as well as their eco-toxicological effects. Moreover, I am developing an offering of services for carrying out Life Cycle Assessment (LCA) analyses and evaluating the environmental impacts of materials. »

Dalyal Copin

R&D Engineer

Environmental impact

“After training in Organismal and Population Biology – Environment at the Université de Bretagne Occidentale in Brest, I had my first professional experience as a laboratory technician at Eurofins Hydrology Ouest, where I acquired skills in physico-chemical analyses as well as some notions of quality.

I joined IRMA in 2023 as a chemical and biological analysis technician. I’m in charge of respirometric analyses of the biodegradation of materials and ecotoxicology tests; I’m also involved in R&D with method/machine optimization and the implementation of quality monitoring within the low-Impact materials division.”

Alizé Levaufre

Technician

Chemical and Biological analysis

“After studying my PhD on biopolymer ageing in marine environments at the Institut de Recherche Dupuy de Lôme, I decided to specialise in biodegradable materials. Finding a different way to design plastic materials as a function of their intended application and integrating the concept of their end of life has huge stakes for the future.

At IRMA, I mainly work on research projects and provide support for physicochemical, thermal and mechanical polymer characterisation services. In parallel, I propose studying the different ways in which materials can age, whether through accelerated ageing in a UV or climactic chamber, hydrothermal ageing or natural ageing in the marine environment… IRMA is also a partner of the European project INdIGO Interreg Projectof which I am scientific director, the goal of which is to manufacture new biodegradable fishing tools and to study their degradation in the marine environment.”

Morgan Deroiné

R&D Engineer

Biodegradable materials

“A chemist and polymer scientist by training, my specialty is using biotechnology to produce bacterial polyesters (polyhydroxyalcanoates or PHAs) that are bio-sourced and biodegradable. Biotechnology allows us to consider bioplastic production as a part of a circular economy by upcycling co-products rich in carbonaceous materials, such as microorganism culture substrates.

I characterise these bioplastics on the structural, physicochemical and mechanical levels in order to understand their properties and thus meet our customers’ expectations.

For example, PHAs have interesting properties in terms of cosmetics applications or for implantable medical devices (e.g. prostheses, dissolvable sutures).”

Pierre Lemechko

R&D Engineer

Chemist

“I’m currently in my final year of a master’s degree in Eco-design of Polymers and Composites at the University of Southern Brittany in Lorient, and I joined IRMA at the start of the 2023 academic year as an apprentice Life Cycle Assessment (LCA) engineer. My main job at IRMA is to conduct lifecycle analyses of products, materials, and processes: this involves assessing the environmental impacts to find out at which stage of the lifecycle the impact on the environment is greatest or comparing scenarios at different stages of the lifecycle. This analysis, which is part of an eco-design approach, enables a product to be designed or re-designed in a more environmentally way.”

Titouan Le Picard

STUDENT ENGINEER

LIFE CYCLE ANALYSIS

“I trained as an engineer and worked my professional career in the field of agronomic research, first in Switzerland and then in Brittany. As early as 1998, I became interested in biodegradable plastics for use in agriculture, before rapidly extending my interest to all other plastics, particularly packaging.

In 2004, just before I retired, I founded the SerpBio association, setting up a laboratory to study the biodegradability of polymers and developing low-cost methods for analyzing biodegradability in soil, compost, freshwater, and seawater.

In 2016, PolyBioAid was created, and I was also its president until the end of 2022, when PolyBioAid was merged with IRMA to become PolyBioAid by IRMA.”

Guy César

EXPERTISE & CONSULTING

BIODEGRADATION

“As the holder of a Masters’ Degree in Electronics and Industrial Computing from the Université de Bretagne Sud in Lorient, I enjoy belonging to an environment that unites research and industry.

I joined IRMA in 2018 and work on additive manufacturing/3D printing, as well as occasionally on research projects and the provision of services.

Manufacturers come to us with questions about new manufacturing technologies, the innovative materials available and/or with parts that they would like to have 3D printed. My goal is to direct and accompany them in their projects from the design phase up until the creation of industrial prototypes and small series.”

Romain Bévan

R&D Engineer

Additive manufacturing

“I have a Master’s Degree in Polymer and Composite Eco-design from the Université de Bretagne Sud in Lorient and have decided to focus on extrusion and the formulation of polymer materials. Following my initial professional experience in the post-consumer plastic materials recycling sector, I later specialised in the development of innovative formulations for FDM/FFF 3D printing applications.

My current task at IRMA hinges on developing new pre-fabricated technical base products for additive manufacturing, as a part of collaborative projects or our R&D service, for a broad variety of fields of application. In doing so, I work with all types of plastics, from natural fibre-reinforced bio-plastics to the most advanced materials for aeronautics applications. I draw from my knowledge of twin-screw extrusion compounding, single-screw extrusion forming, 3D printing and various characterisation skills in order to best meet the needs of IRMA’s customers and partners.”

Clément Denoual

R&D Engineer

Materials & Additive Manufacturing

“A materials engineer by training, I use 3D printing to manufacture prototypes, mock-ups and functional parts as well as to work on automated fibre placement (AFP) foil manufacturing.

I am currently in charge of the Gwalenn Du project, which aims to develop the manufacturing of fishing rods using thermoplastic filament winding in partnership with Nautix and FIIISH. It seeks to relocate the manufacture of these elements while simultaneously improving the quality and recyclability of objects. This technology could also be used in the hydrogen sector for manufacturing reservoirs.

I am also working on the development of the AFP-XS, a fibre placement robot that operates integrated with Rhino CAD software, in order to diversify IRMA’s catalogue of services.”

Léo Talotte

R&D Engineer

Composite materials

“As someone who is passionate about high-performance composite materials, I have been responsible for AFP (automated fibre placement) and characterisation at IRMA since 2018.

I advise our customers regarding their choice of materials as well as the manufacturing strategy required in order to comply with their desired resistance requirements. I work with technical parts applied to water sports (aerodynamic appendages for IMOCA/Ultim) or aeronautics. Moreover, we are now offering our skills to stakeholders in the hydrogen applications sector.”

Kévin Henry

R&D Engineer

Composite materials