Low-impact materials

Fabricated base product formulation: specific-purpose materials

The formulation stage, which is also called ‘compounding,’ is a process allowing to mix molten plastic materials and filler additives.

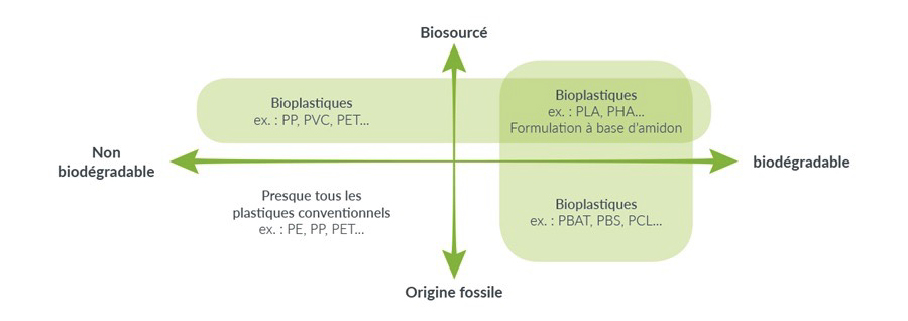

The term bioplastic refers to plastic materials whose origin is different from their end of life. In reality, it covers three families of polymers:

– Polymers that are bio-sourced and biodegradable (PLA, PHA…)

– Polymers that are bio-sourced and non-biodegradable (PA 11, bioPE, bioPET…)

– Polymers that are neither bio-sourced nor biodegradable (PBS, PBAT…)

Classic application of polymer materials (injection, extrusion, thermosetting, thermocompression…)

- Improvement of mechanical properties by strengthening the bioplastic matrix, both through mineral fillers (talcum powder, oyster shell powder…) and plant fillers (wood flour, plant fibres such as flax, jute…)

- Functionalisation of materials: UV stabilisation, control of degradation and/or biodegradation kinetics…

For all materials (as a function of the quantity of material available, different machines may be used):

- Small quantities (less than 250 g): Brabender internal mixer (UBS)

- Medium quantities (between 500 g and 2 kg): Brabender counter-rotating twin screw extruder (UBS)

- Large quantities (more than 2 kg): TSA FSCM 21 co-rotating twin screw extruder (UBS)

To produce new PHAs at the laboratory level:

- Rotary agitator and incubator (up to 8 Erlenmeyer flasks 1 L) (UBS)

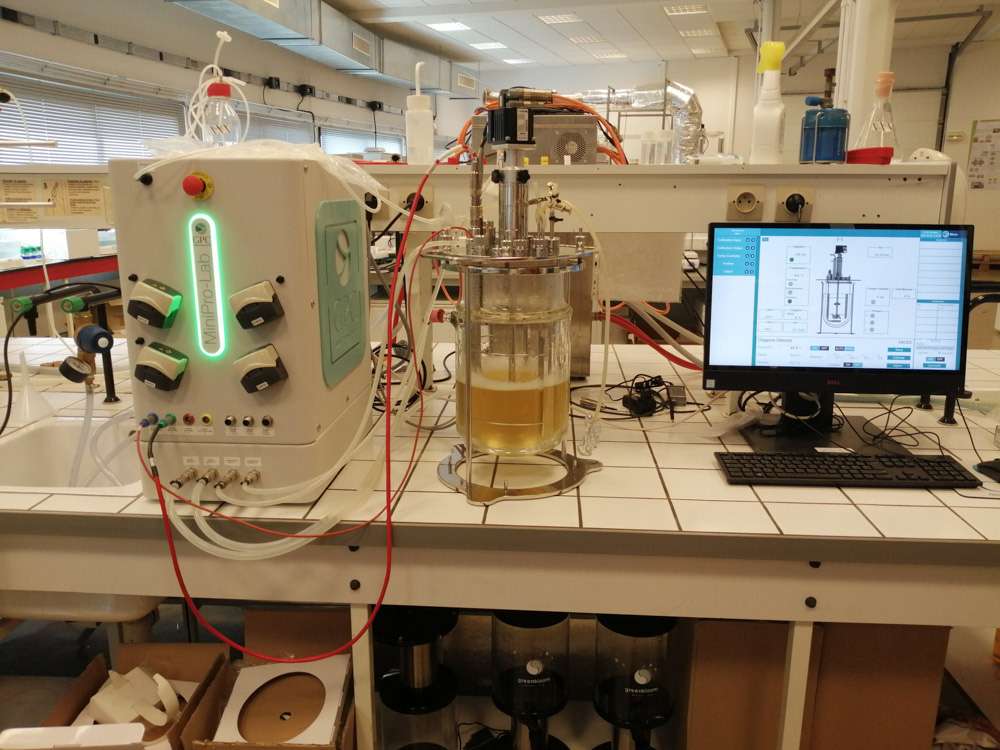

- GPC bioreactor with 1 L and 5 L tanks (UBS)

Ludovic software (optional): àsimulation of co-rotating twin screw extrusion compounding

Application

In cooperation with the Université de Bretagne Sud (UBS), IRMA possesses different application machines that can be used to transform your formulations in the molten state.

- Extrusion : mise en œuvre de film plastique, de filament pour impression 3D, de section tubulaire, de monofilament….

équipement : extrudeuse monovis Scamex (L/D = 20 et diamètre = 20 mm, température max = 450°C, débit = 1-4kg/h) - Machine d’étirage : 7 rouleaux chauffants installés en sortie d’extrudeuse

équipement : machine Retech - Injection (UBS) : mise en œuvre d’éprouvette de type haltère pour essais mécaniques (traction, choc…)

Équipement : presse à injecter Battenfeld HM (80/120) - Thermoformage (UBS) : moule standard testeur ou réalisation de moule sur mesure

équipement :

- Broad diversity in the application of your formulations

- Ideal for manufacturing test pieces for new material technical data sheets

- Extrusion: Scamex single-screw extruder (L/D = 20 and diameter = 20 mm, max. temperature = 450°C, speed = 1-4 kg/h) (ComposiTIC): application of plastic film, filament for 3D printing, tubular sections, monofilament…

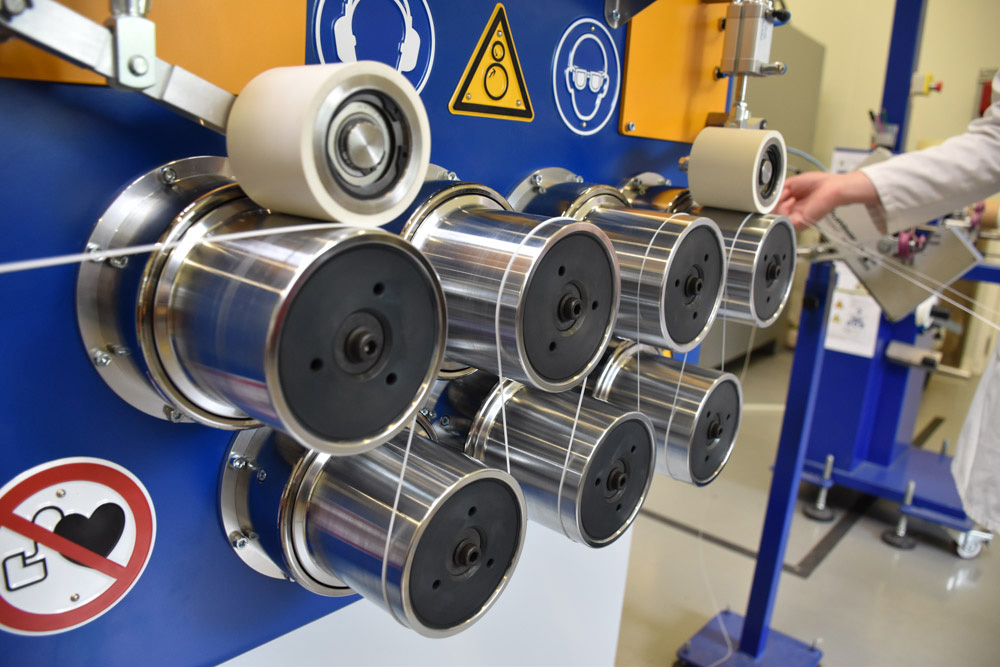

- Retech stretching machine: 7 heated rollers installed at the extruder exit (ComposiTIC)

- Injection: Battenfeld HM injection moulding press (80/120) (UBS): use of dumbbell test pieces for mechanical testing (traction, impact…)

Characterisation

Our characterisation techniques allow us to evaluate the physical, chemical and thermal properties of different materials and parts. Samples can be provided directly by the customer or created by us using the procedures described in the ‘Application’ section.

Samples of materials to test are taken in different ways depending on the properties measured. Some tests are non-destructive (X-ray computed tomography) while others are destructive (mechanical tests, microscopy…). They make it possible to measure material resistance, their degree of polymerisation, void ratio, changes in properties over time for materials subject to different types of ageing…

- Quality control of raw materials or finished products

- Analysis of failures and proposing of solutions

- Technical decisions and process improvement

- Reverse engineering of products through the characterisation of competitor products

- Mechanical characterisation

- Traction / compression testing: Instron 10kN (ComposiTIC) or 100kN (IRMA)

- Flexion testing

- Fatigue

- Morphological characterisations

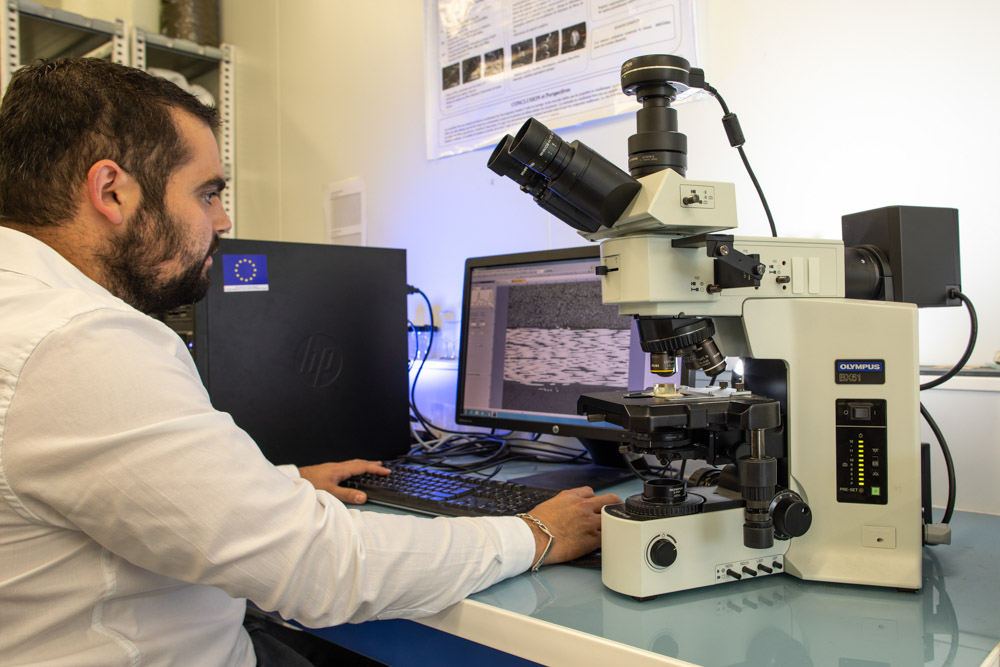

- Microscopic analysis: microscopy, scanning electron microscopy (SEM)

- Determination of the void ratio

- Density measurement

- Ash content

- FASEP fibre length measurement (ComposiTIC)

- Hardness analysis

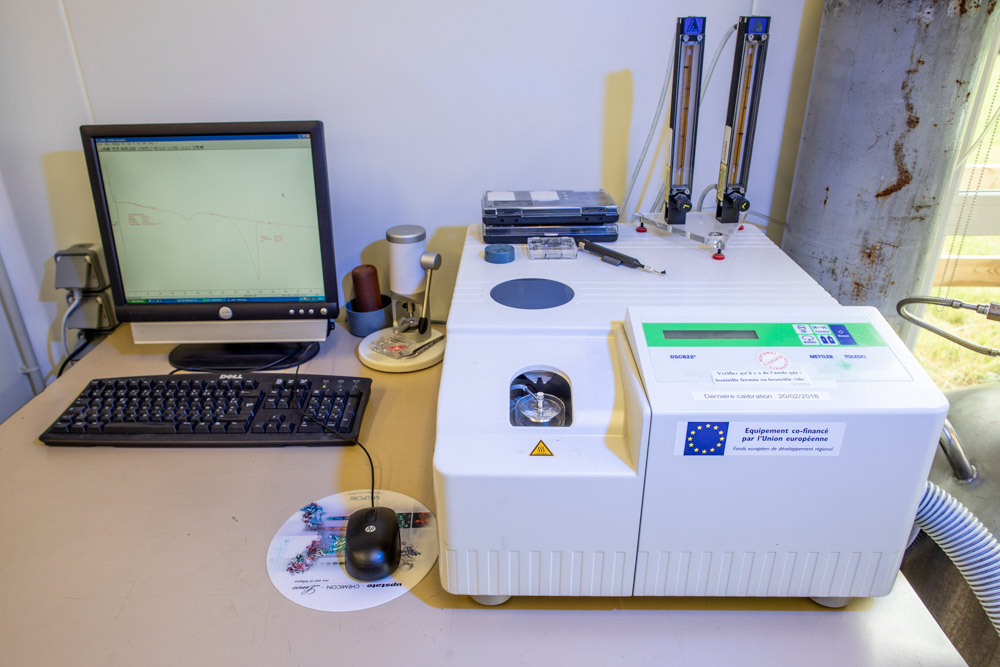

- Thermal characterisations: DSC and ATG (UBS)

- Eco-toxicity analysis

Ageing

In real life, materials are subject to humidity and sunlight and their properties deteriorate.

‘Ageing’ is the term used to describe any phenomenon consisting of slow and irreversible changes in the structure and/or composition of a material as a result of its instability, interaction with the environment, mechanical forces or coupling.

Material ageing under real use conditions is characterised by slow degradation kinetics. The use of accelerated testing is therefore necessary in order to quantify ageing in the laboratory and to thus evaluate the durability of a material or structure.

IRMA gives you the possibility of studying the natural ageing of materials in the marine environment as well as accelerated ageing under harsh humidity and temperature conditions, during immersion in distilled water, when placed in a UV chamber…

- Improved knowledge of materials = provides guidance regarding use decisions

- Meets needs in terms of compliance with legislation in force (voluntary regulations)

- Creation of materials libraries to address client-specific issues

- Accelerated UV ageing: study of accelerated material ageing in a Solarbox UV chamber in accordance with available standards: ASTM D6551 (packaging), ISO 4892-2 (plastics), ISO 105-B02 (textiles)…

- Equipment: Solarbox 3000e chamber (IRMA)

- Hydrothermal ageing: study of ageing when immersed in distilled water at different temperatures: monitoring of water absorption; monitoring of changes in mechanical, thermal and physicochemical properties.

- Device used: Julabo thermostatically controlled bath (IRMA)

- Natural ageing in the marine environment: study of the natural ageing of materials submerged in a marine environment: monitoring of water absorption; monitoring of changes in mechanical, thermal and physicochemical properties.

- Equipment: Japanese lantern net suspended from a pontoon in the Port of Lorient (Kernevel)

- Hygrothermal ageing: study of ageing in a temperature- and humidity-controlled chamber [T= 25-200°C – RH=0-100% RH]: simulation of climatic conditions (dry or humid climate), accelerated conditioning of polyamide (PA) test samples prior to mechanical testing (standard ISO 1110)…

- Equipment: SECASI SLH 100/70 VRT hygrometric chamber (UBS)

End of life

The environmentally responsible materials of the future: two complementary approaches

Studying biodegradation is the last stage of plastics ageing and provides a more comprehensive picture. Biodegradation criteria are associated with specific standards, and are directly related to a timeframe that will depend on the incubation environment and the temperature.

In parallel, the impact of degradation products on the land or marine ecosystem can also be studied through eco-toxicity tests. These are experimental tests that determine the effect of products on a select group of living organisms under well-defined conditions.

- Biodegradation is studied in accordance with all standards in force in different environments, including in industrial and household compost, fresh water, the sun and the marine environment. This monitoring is made possible by the kinetic monitoring of the carbon dioxide produced by microorganisms throughout the process of the material’s bio-assimilation.

- Studying a material’s toxicity with respect to its environment (the marine environment in the case of the tests carried out at IRMA) takes place at multiple trophic levels (copepods, microalgae, bivalves). This stage may take place subsequent to ageing stages.

- Primarily to protect natural environments

- Better knowledge of materials = provides guidance around which materials to use

- Meets needs in terms of compliance with regulations in force (voluntary regulations)

- Creation of materials libraries to address client-specific issues

- MODA-9 Microbial Oxidative Degradation Analyser (IRMA)

- Customised assembly for monitoring in thermostatically controlled chambers / water bath (IRMA)

- Microscope (UBS-LBCM)

- Phytotronic chamber (UBS-LBCM)

LCA

Life cycle assessment (LCA) is a comprehensive, transparent and multi-criteria technique that is particularly relevant for eco-design processes. This technique uses an internationally standardised method to evaluate the potential environmental impacts of a plastic, or more generally a product, at each stage of its life cycle, from the cradle to its end of life.

Biomaterials development enables a new approach—called ‘cradle to cradle’—in which products at their end of life are considered a new source of energy or material

A new standardised method (ISO 14040) allows to identify and quantify all incoming and outgoing flows throughout the life cycle of a product or service in order to evaluate and compare environmental impacts.

In this sense, this method is an excellent tool in a eco-design process because it allows to evaluate different competing solutions from the environmental standpoint.

SimaPro 8 Life Cycle Assessment Software