Additive Manufacturing

Additive manufacturing processes

Design

We use a combination of the composite technical materials available and additive manufacturing processes to create parts that meet technical and financial requirements.

IRMA accompanies you in the process of defining your projects and writing your technical specifications.

We are committed to assisting you in the design or reverse engineering of high-tech products that meet mechanical, thermal and other demanding physical performance requirements, thus supporting you in your technical decisions.

IRMA provides you with high-quality accompaniment by taking into account the product, material, processes, choice of concepts and pre-dimensioning, thus participating in the creation of a study that is consistent in terms of its technical and financial aspects, in cooperation with its customers. Your product will be dimensioned with the right materials in the right places, using finite element analysis tools. Computer-aided design (CAD) knowledge is a comprehensive part of our dimensioning service, allowing us to predict and specify a part’s performance requirements.

In-depth reports and analyses enable your product to be reverse engineered while complying with your requirements (weight, cost and mechanical performance). Through our product study, the final definition of the product (dimensions and CAD of the product) and our manufacturing means, we are capable of creating and characterising your prototypes and products. To do so, our Design Department is capable of defining the manufacturing stages and methods suitable for single-unit or series manufacturing.

Simulation cluster consisting of three calculation engineers

x 3 calculation workstations

CAO :

- Rhino 6

- Fusion 360

- Solidworks

Simulation :

- Aniform

- Comsol

- Fortran

- Nastran

Processes :

- Simplify3D

- ARM RTM

- Mach3

Formulation

Our plastic material formulation capabilities allow to adjust materials’ properties to the requirements of different fields of application.

These formulations can be applied in different ways, such as via extrusion to manufacture a fabricated base product for FFF 3D printing or the impregnation of fibres with TD or TP matrices to create tapes. We use extrusion, injection, thermoforming and thermocompression to create parts. We can work with any thermoplastics, from biomaterials to the most complex polymers for aeronautic applications. Our formulations are based on mixtures of polymers and reinforcements (different fillers, natural fibres, fiberglass, carbon fibre…) to meet different technical specifications (thermal, mechanical or electrical properties…).

- Improvement of mechanical properties through reinforcement of the plastic matrix using short fibres (glass, carbon, aramid fibre, flax fibre…) or fillers (talcum powder, wood flour…).

- Functionalisation of materials as needed: UV stabilisation, electrical conductivity, thermal conductivity…

Our formulation equipment:

- Compounding via co-rotating twin screw extrusion (TSA) powered by two gravimetric dosers (ComposiTIC)

- LUDOVIC twin screw extrusion simulation software (ComposiTIC)

Our fabricated base product application equipment:

- Struers CITOVAC vacuum impregnation unit (TP or TD) (IRMA)

- Extruder: Scamex (ComposiTIC)

Additive manufacturing

Additive manufacturing is a process that allows to manufacture 3D objects based on a digital file. It is called ‘additive’ because the construction of parts is based on the superposition of material layers. This technology allows to produce complex shapes that it would be difficult to create using traditional moulding or machining methods or other subtractive technologies.

All digital manufacturing starts with a comprehensive 3D model in order to enable fibre placement following a stacking plan that indicates the areas to reinforce. This model is sectioned in accordance with the machine’s features in order to create placement paths that are adapted to the part.

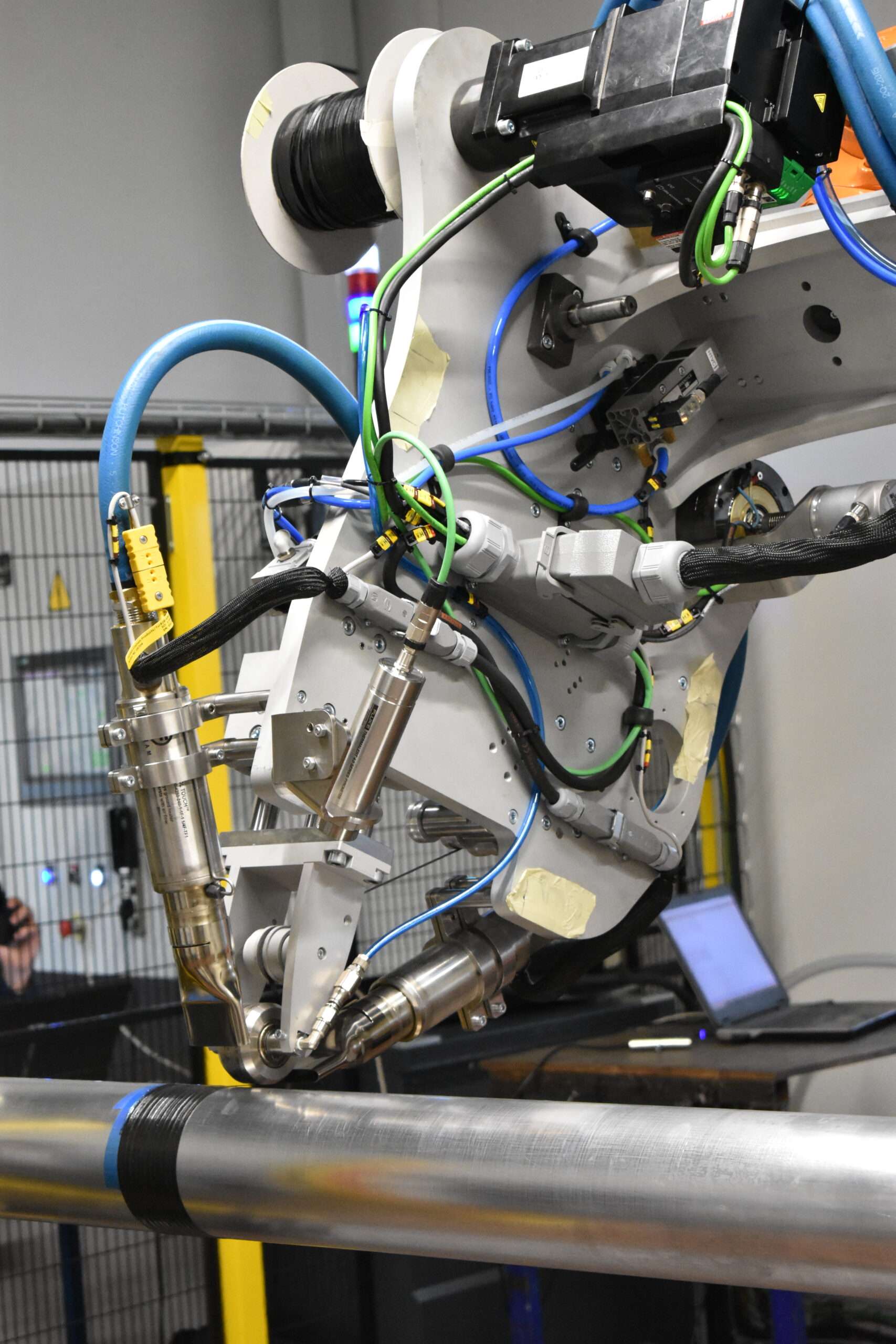

- AFP (automated fibre placement): Layers of fibres are placed on a mould by a robotic arm. The part is then cooked following stacking.

- I3D: 3D printing places a filament of melted plastic material, sometimes combining continuous-fibre reinforcements.

- Filament winding: Winding of fibres around a rotating mandrel by a robotic arm. The part is then cooked following stacking.

I3D:

- Good mechanical and thermal properties (> 200°C)

- Soluble printing media can be used in order to create parts with complex geometries

- Good geometric resistance

- Continuous reinforcement (carbon, glass, Kevlar, basalt) for industrial applications requiring resistance and solidity

AFP:

- Better quality and increased repeatability compared to manual composite application

- Excellent mechanical properties

- Quick to manufacture

- Possibility of placing reinforcements very accurately, even on existing parts.

On a single given complex part, IRMA may use both types of manufacturing (I3D and AFP). IRMA is specialised in combining different manufacturing procedures.

Filament winding:

- Manufacturing of perfectly symmetrical rotating parts

- Better quality and increased repeatability compared to manual composite application

- Excellent mechanical properties

- Quick to manufacture

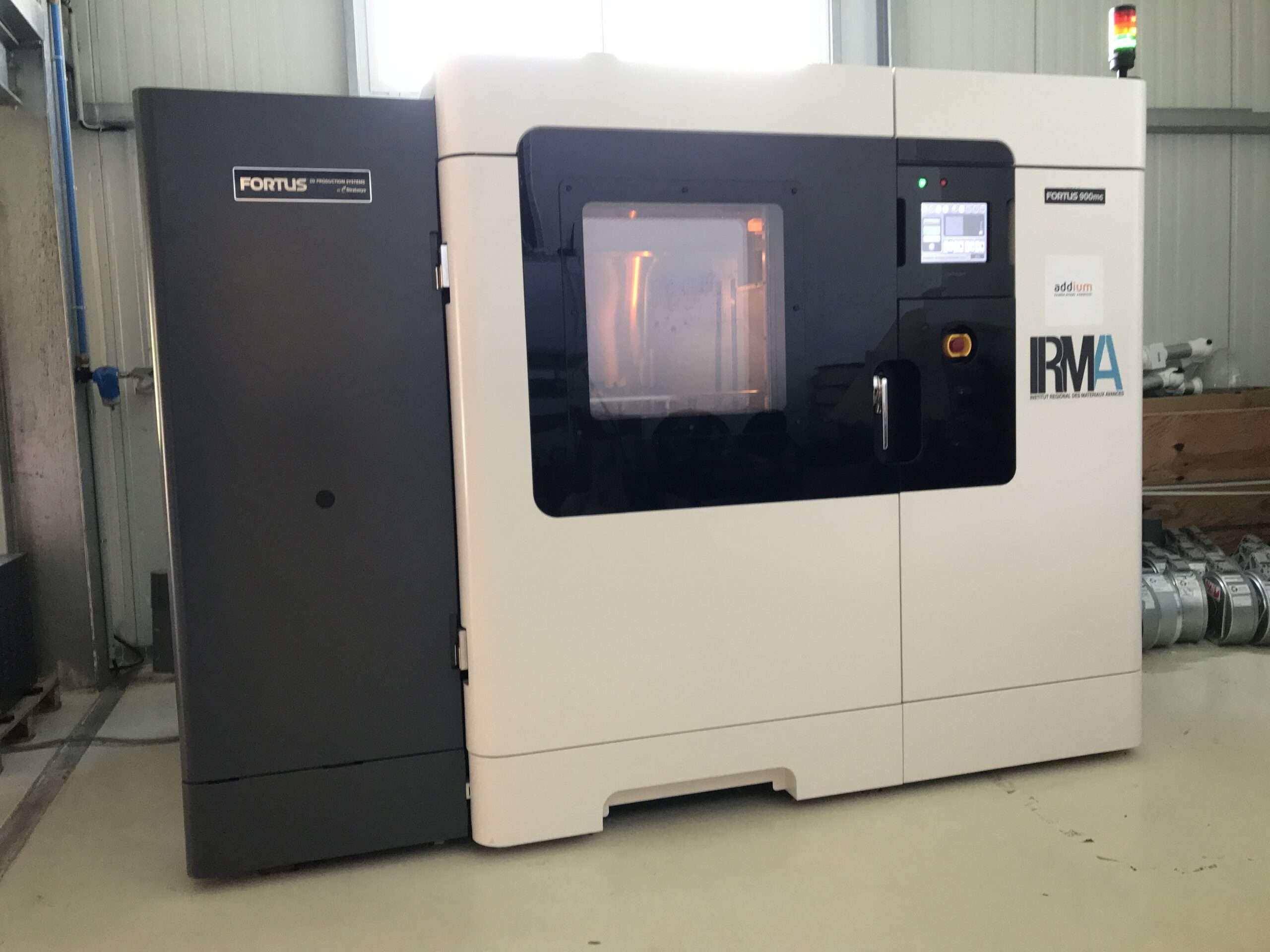

I3D

- Fused deposition 3D printing:

- Stratasys Fortus 900mc (IRMA)

- Modix BIG 120X (IRMA)

- Large choice of short-fibre thermoplastics and/or composite materials (ABS-CF, PC, PEI, PLA, PEEK)

- Large-format dimensions: FDM: 90 x 60 x 90 cm / FFF: 120 x 60 x 60 cm

-

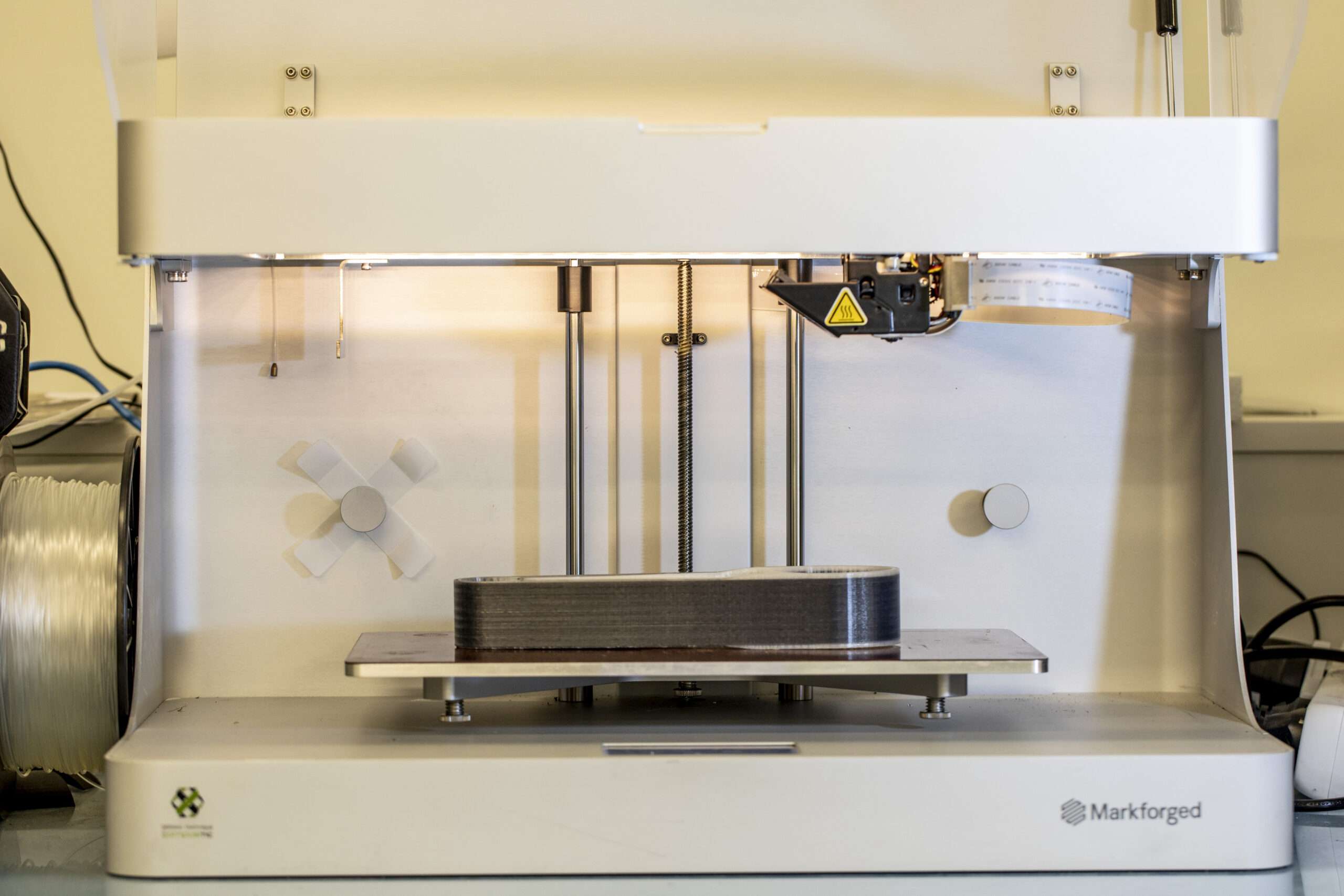

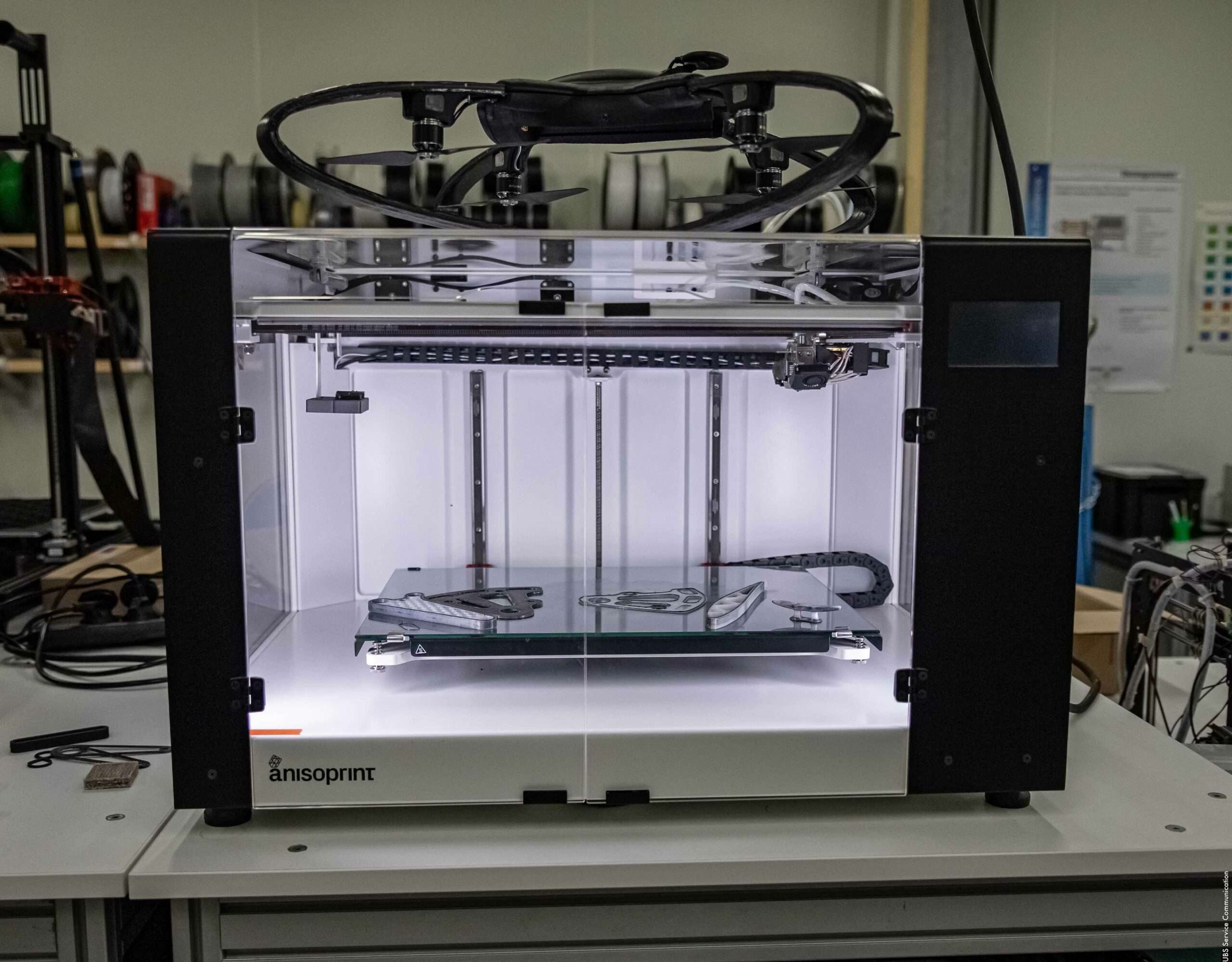

- Continuous fibre-reinforced 3D printing:

- Markforged Mark Two (ComposiTIC)

- Anisoprint Composer A3 (IRMA)

- Fiberglass, carbon and Kevlar reinforcements

- Printing volume: Markforged: 32 x 13 x 15 cm / Anisoprint: 42 x 29 x 21 cm

AFP:

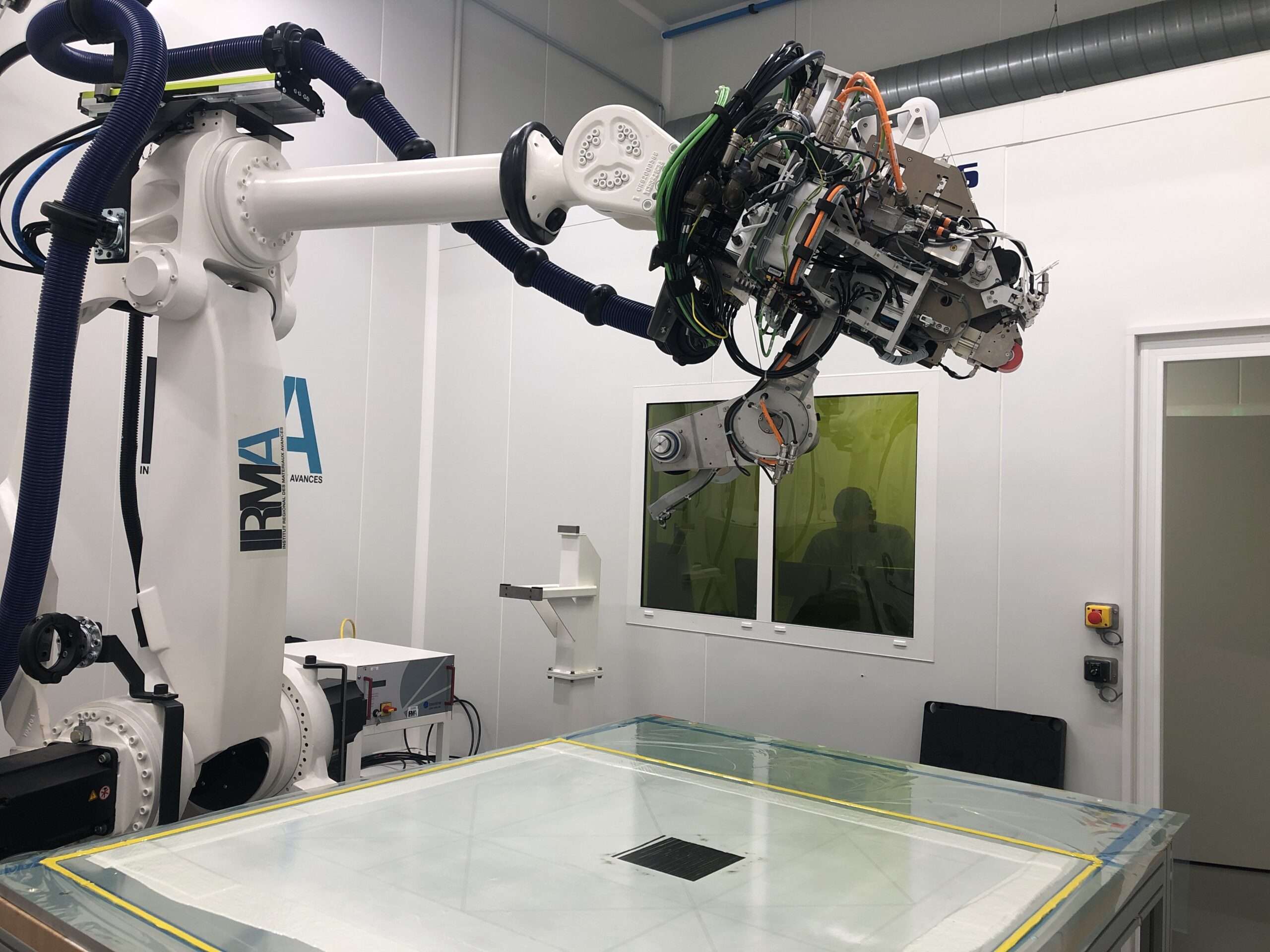

- Coriolis C-Solo (IRMA):

- Placement of fibres measuring between ¼ and 1 ½ inches on a surface plate or a mould.

- Dry, thermosetting or thermoplastic fibre, with laser heating and Optic Zoom (optional)

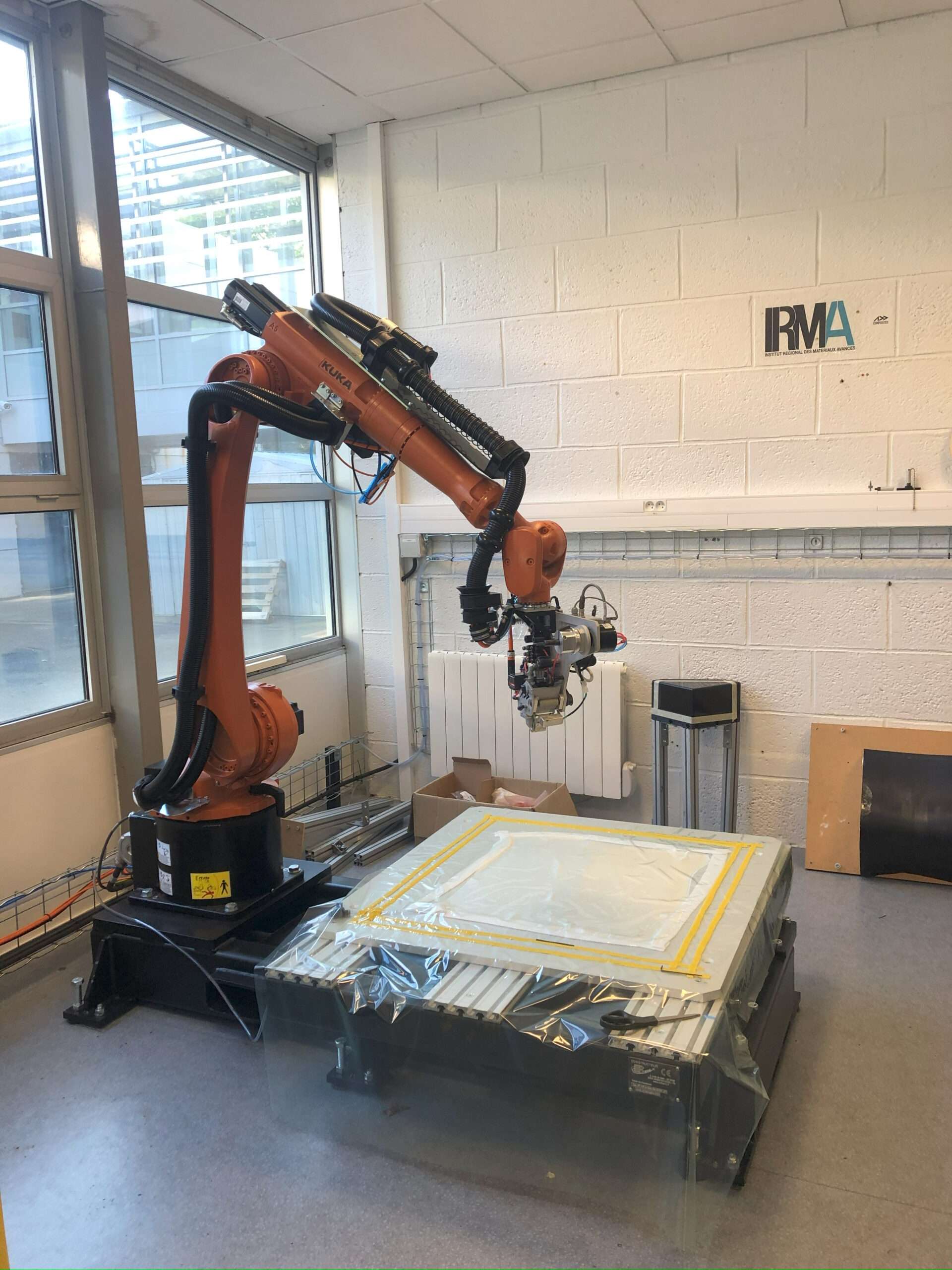

- AFP-XS (IRMA):

- Compact head for placing ¼ inch fibres

- Simple to program, integrated with Rhino3D

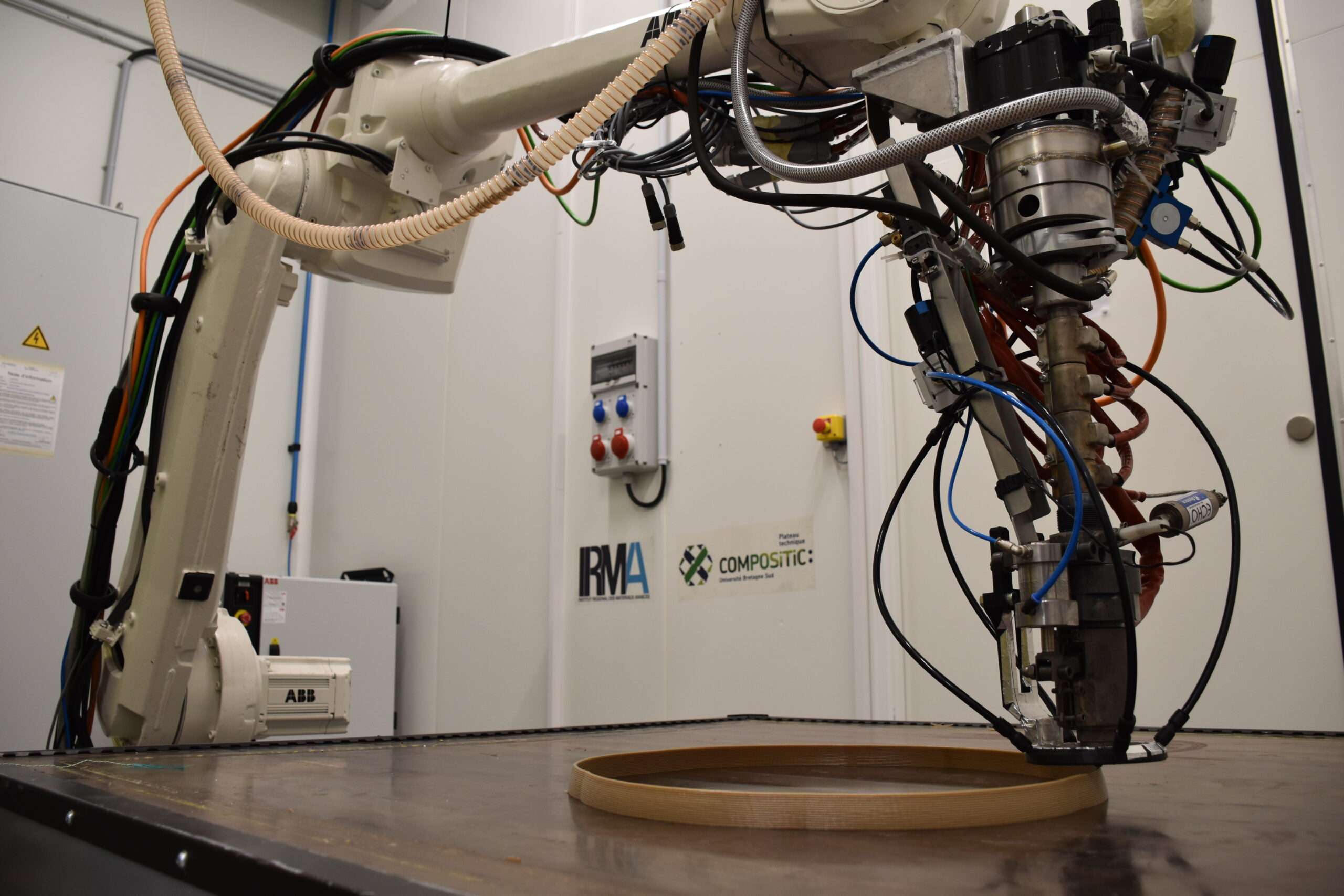

- Coriolis C1 (ComposiTIC):

- Placement of 8 x ¼ inch fibres on a surface plate or mould.

- Dry, thermosetting or thermoplastic fibre, with laser heating and Optic Zoom (optional)

- Nabertherm High-Temperature Oven (IRMA)

- Surmoul 3D I3D Cell – Extruder L/D=15 – D=16 mm – 6 axes/surface plate (IRMA)

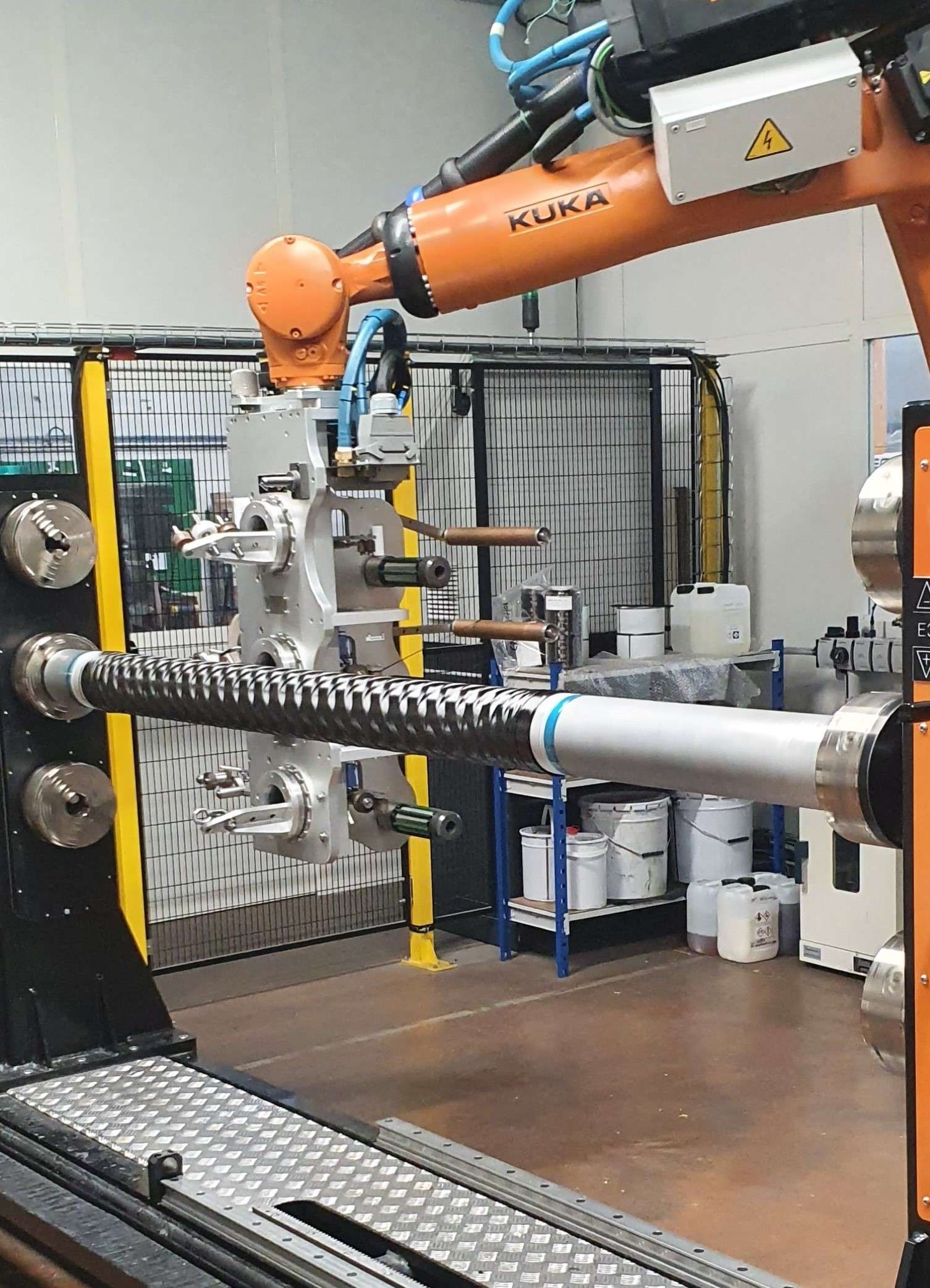

Filament winding:

- Thermoplastic head for the filament winding of thermoplastic fibres measuring between ½ and 1/8 inches up to 250° (IRMA)

- Filament winding machine (located at a partner company) for parts up to 4 m long and 1 m in diameter

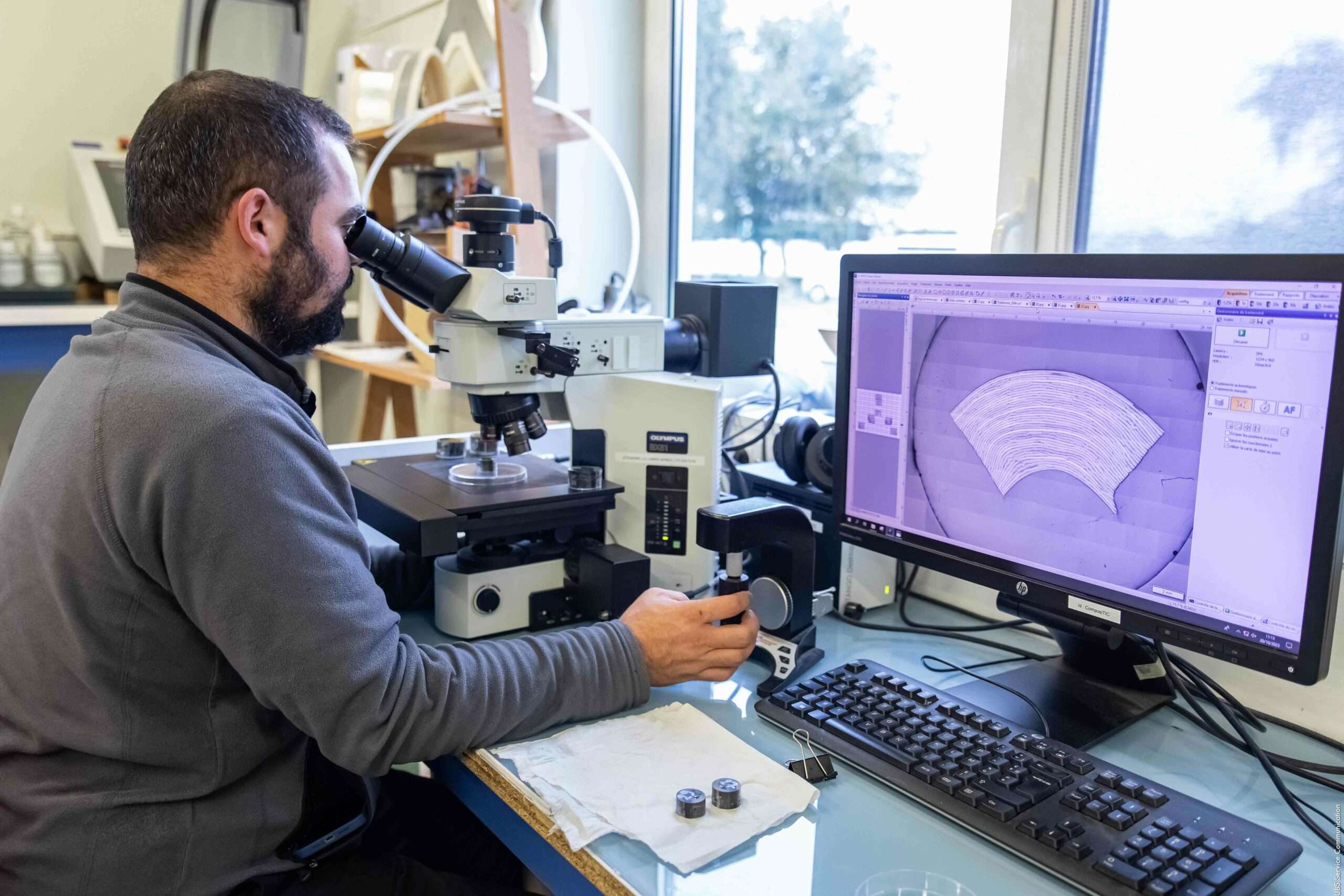

Characterisation

Our characterisation tools allow us to evaluate the physical, chemical and thermal properties of different materials and parts. They can be applied to product-related services, to samples provided by customers or during the fine-tuning phase for new materials and processes.

Samples of materials to test are taken in different ways depending on the property being measured. Some tests are non-destructive (X-ray computed tomography) while others are destructive (mechanical tests or microscopy). They make it possible to measure material resistance, their degree of polymerisation, void ratio and more…

- Quality control of raw materials or finished products

- Analysis of failures and proposing of solutions

- Technical decisions and process improvement

- Reverse engineering of products through the characterisation of competitor products

- FASEP fibre length measurement (ComposiTIC)

- Instron 10kN traction and fatigue testing machine (ComposiTIC)

- Instron 100kN traction testing machine (IRMA)

- Thermal analysis (DSC=ComposiTIC)

- Optical microscopy (ComposiTIC): motorised focusing stage for panoramas

- Jeol or MEB scanning electron microscope / EDX probe (ComposiTIC)

- Dynamic mechanical analysis (DMA) (UBS)

- X-ray computed tomography (at a partner company): material health (density, porosity…)

Upcycling / Recycling

Today, composite thermoplastic parts are often not recycled. The benefits of upcycling these materials—which are very valuable in terms of performance and financial viability—should be clear when considering the environment.

- Sorting different types of plastic

- Washing if necessary

- Comminution to obtain adequate particle size

- Formulation via extrusion

- Potential use in different plastics manufacturing processes…

The goal of mechanical recycling is to melt down and reformulate a thermoplastic polymer in order to give it a second life.

- Mills: Shr3it: Reversible direction comminution shredder + granulator combined with a rotary blade cutter + calibration panel (ComposiTIC

- Mills: 2 rotary mills + calibration panel (CMB + Retschmühle) (UBS)

- Equipment in the formulation line